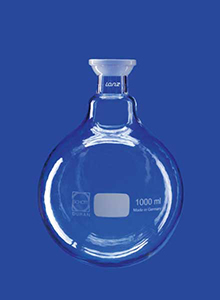

PUR coating

New: PUR coating, autoclavable

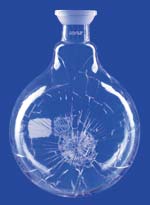

In a special process, the highly transparent polyurethane-based coating is applied in defined film thicknesses to glass components, irrespective of their shape. The coating provides protection from light, impacts and scratches in everyday laboratory operations. In the event of glass breakage, the coating provides protection from shattering and leakage. We provide PUR coating on most of our laboratory glassware on request.

| Physical properties/resistances | ||

| Autoclavability | up to 121 °C, up to 2,05 bar (up to 100 cycles à 20 min) | |

| Transmission | Adsorbtion up to approx. 380 nm | |

| Temperature resistance | ||

| Long-term heat resistance | up to 140 °C | |

| Short-term heat resistance | up to 190 °C | |

| Freezing resistance | up to -30 °C | |

| Microwave resistance | yes | |

| Chemische Eigenschaften/Resistenzen | ||

| Water | up to 100 °C | |

| Organic solvents (room temperature/5 min. constant exposure) | ||

| Alcohol | yes | |

| Acetone | yes | |

| Tetra | yes | |

| Anorganic acids/bases (room temperature/5 min. constant exposure) | ||

| Hydrochloric acid | up to 20%ig | |

| Nitiric acid | up to 20%ig | |

| Sulphuric soda | up to 20%ig | |

| Caustic soda | up to 20%ig | |

| Further restistances | ||

| Disinfectants | yes (customary) | |

| Detergents | yes (customary) | |

| Industrial/clinic washers | max. 95 °C (up to 50 cycles) | |

| Household dishwashers | max. 65 °C (up to 50 cycles) | |

Test Certificates/Conformities

• Increased impact resistance acc. to DIN 52337 and DIN EN 12600

• Fire performance on glassware acc. to DIN 4102 part 1

• Free of substances of Very High Concern acc. to the ECHA candidate list

(status: 01.02.2010)

• An appropriate coating is after its curing process physiologically harmless

(status: 16.12.2009)